SOLUTION

|

|

Kinda varialbe frequency inverter applied in pumps and fans

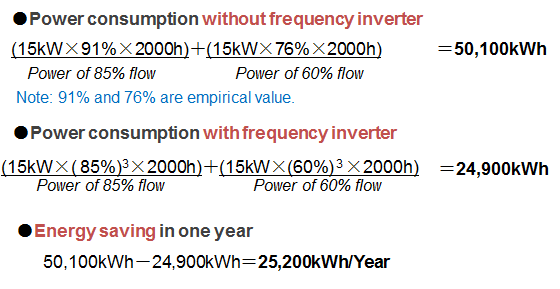

(2) If without VFD, the fluid is controlled by valve or baffles; (3) For less fluid required system, there will be more energy saving. (4) In theory, if the running frequency is H1, then Energy Saving = 1-(H1/50)3 (2) VFD should work continuously without fault. (3) Speed tracking and start (flying start) function should be reliable. (4) In some systems, PID function is required. 3, Real example In a hotel, there is an central air-conditioner, the cooling fan is one PCS of 15kW motor, in one year, it runs 4000h, 2000h with the air flow of 85%, 2000h with the air flow of 60%.  5, Parameters setting list

6, Notice Maintenance regularly, pay attention to dust and humidity prevention. |